For the Holder Material option, there are typically two types of LED holder on the market: Aluminum and Copper. Most other sellers do not tell what kind of material they are using especially when price matters. Copper Holder is better than Aluminum in thermal performance which will extend the LED life in a longer way. While they are all till plated, it looks very similar by visual. How to different them? Literally there are two commonly used methods:

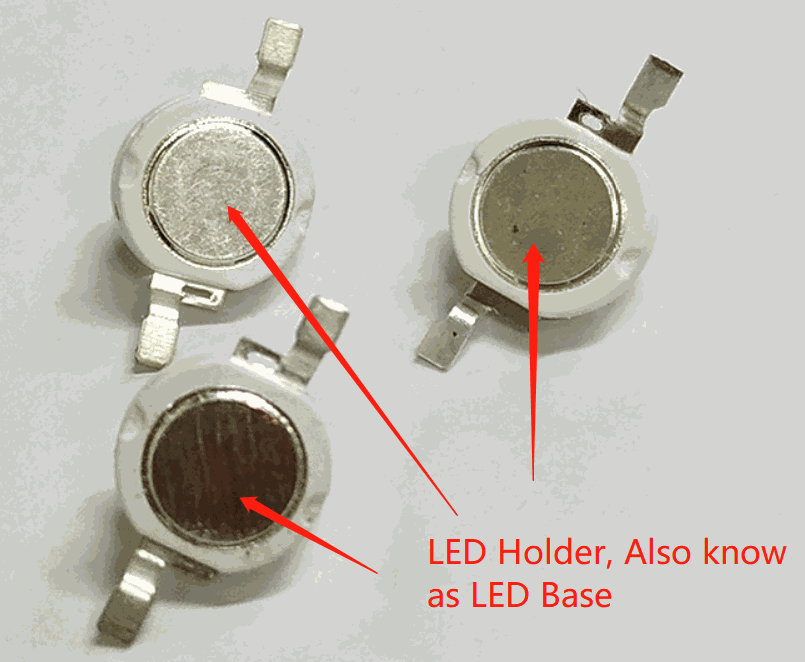

What is LED Holder

The LED holder, also known as LED Base, is the base where the LED dies(chips) sit. By encapsulating the tiny chips in to the LED holders, the LEDs can be widely used on various lighting fixtures. The material of the holder are cost differently. The whole industry mainly use two materials for them: Aluminum and Copper. While copper is more expensive and better in heat dissipation, the cost is relatively higher.

1. For the Aluminum Holder, the material is actually aluminum-iron mixed. If you hold a magnet get close it, the aluminum ones will be picked while the copper one will not.

2. Scratch the bottom or the leg of the copper one, you will find the copper are with copper color while the aluminum ones are still white.

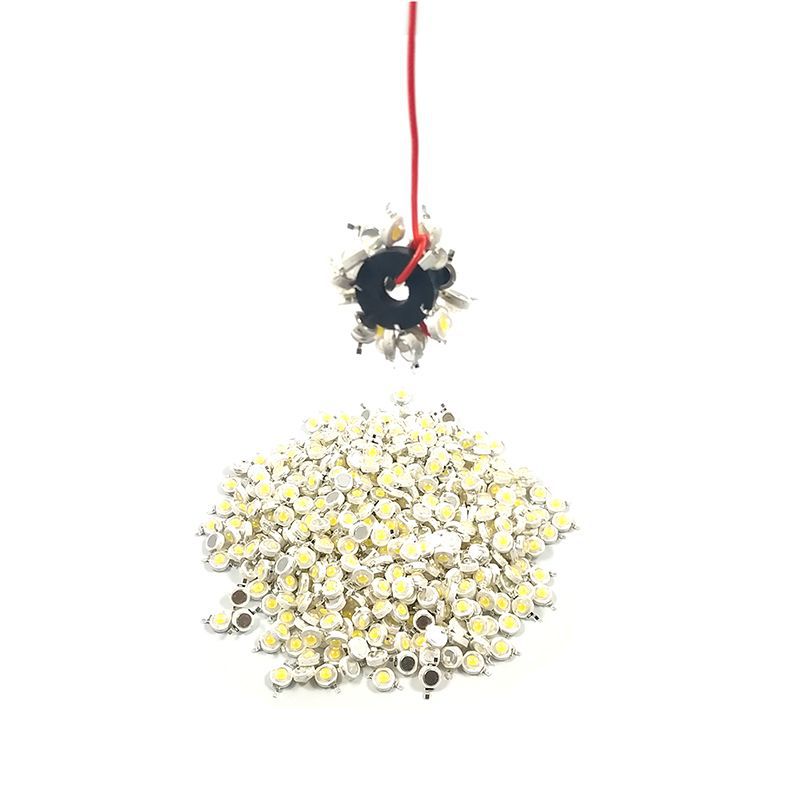

Aluminium Base LED Package

Since Aluminum based LED is Cheap, the regular package for them are Anti-static bags. For factory package, we do 1000pcs/lot package. Since our cart start with 1pcs for all, we will pack them with smaller Anti-static bags for small quantity orders

Copper Base LED Package

For copper based LED, we regular pack them with anti-static tubes. It is also an industrial practice. One anti-static tube can hold up to 50pcs/tube. But in our practical order process, we normally put them in to small anti-static bags too to minimize the length of the package. In the case of you order dozens tubes or your total order package is large enough, we will use the tube packaging.

LED Holder/Base Material Difference

Aluminum vs Copper